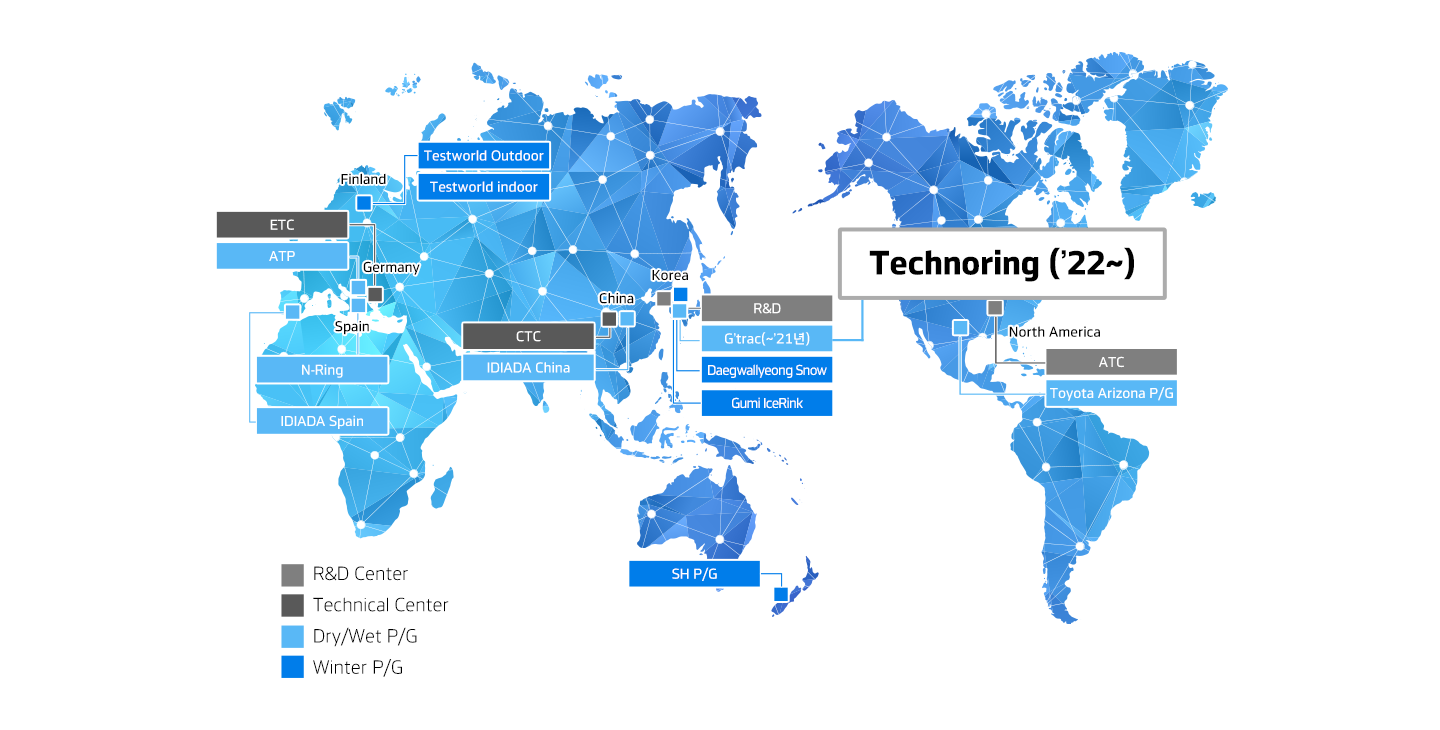

Flagship Proving Ground, Hankook ‘Technoring’

In May 2022, Hankook Tire opened Asia's largest test track, Hankook Technoring (hereafter Technoring), covering an area of 38.15 million pyeong (A combined area of 125 soccer fields). Based on Hankook Tire’s philosophy of technology, Technoring serves as the final test bed for rigorous testing of all tire technologies. This launched Hankook Tire's high-speed driving towards the pinnacle of technology.